If you have ever spent a lot of time crafting an amazing base just to have the mini keep coming loose, you are not alone. We put all kinds of things on our bases so that they look great. This practice isn’t the best for creating a surface that things stick to well. Pinning is one way to get things to stay put. I will show you how I connected my model to the volcanic lava base that I made for this article.

Materials that you will need for this project

Why should you pin your model to the base?

Pinning miniatures to their bases helps them to stick better for several reasons. It increases the surface area for the glue to hold, it adds rigidity to the structure of your model as a whole, and it holds from well above the point of contact to well below the bottom of the base.

The steps to pinning your mini to its base

- Decide where you want to place your miniature on the base

- Align the pin placement between the miniature and the base

- Use a pin vice to drill a hole in your model and a corresponding hole in the base

- Cut a pin to the correct size

- Dry fit the pin

- Glue the pin in place

1. Decide where you want to place your miniature on the base

Before you make any holes in your model or the base, make sure that you have decided on exactly how you want the model to be posed. Once you have drilled your holes it is too late to easily change your mind.

Because the pin will add strength you don’t have to choose a place where your model and your base meet flush. I generally try to pin in the heel or middle of a foot if possible. Adding a pin to that spot allows for the pin to go slightly into the leg of the model without worrying about it poking through the top of the foot etc.

If your model is posed more dramatically, look for any place where the model will be in contact with the base and that will be where you can hide the pin from sight.

If your intent is to make your model look like it is hovering over the base instead of touching it, there are a couple of things to consider. You could paint your pin black, or otherwise, camouflage it to make it less obtrusive. You could purchase a flight stand that comes with some models that are intended to fly. These are clear plastic stands that lift the model above the base to simulate flying.

2. Align the pin placement between the miniature and the base

If the hole in your miniature and your base don’t line up properly, the placement of the miniature will be off once you have them assembled.

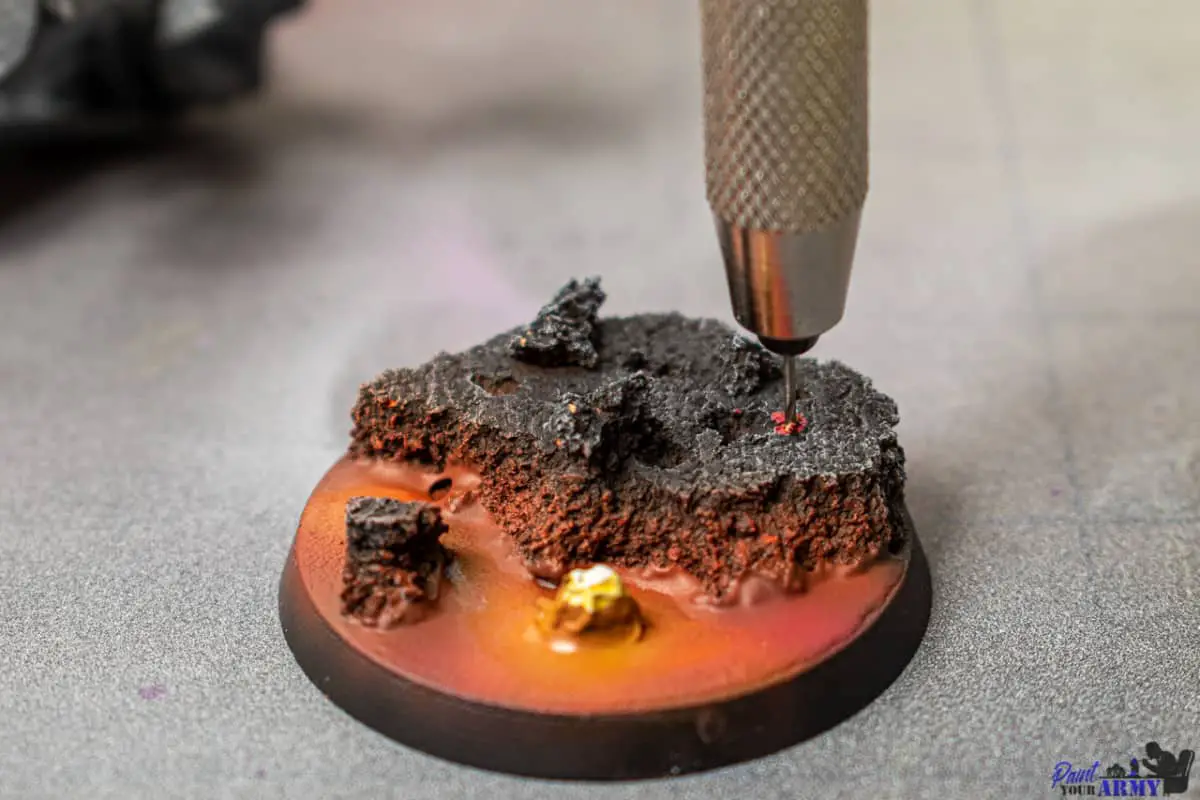

One trick that I use to ensure that they line up in exactly the right spot is to take a dot of paint and put it in the place I want to drill at the bottom of my miniature. Then before the paint has a chance to dry, I gently press it into place on the base where I want it to go. The dot will transfer from the mini to the base leaving a small amount of paint on both surfaces marking the place to drill. In the image below, I used red paint because it would contrast with the black base, and I could see it easily.

3. Use a pin vice to drill a hole in your model and a corresponding hole in the base

The bits from your pin vice will come in a variety of sizes, I hold them end to end with the brass rod that I intend to use so that I can make sure that they are close to the same size.

Use the thinnest brass rod that you have available for small models. Use the thicker pieces for large heavy pieces that really rely on them for structural stability.

Once you have chosen the thickness of your pin, use the corresponding bit to drill a small hole through the basing material until your bit pokes through the base. then drill a hole of the same diameter into your miniature where you placed the paint dot. Be careful that you are drilling at the correct angle. It may seem slow to do this all by hand but it is worth it.

Avoid the urge to clamp the bit into an electric drill. You are working with soft plastic and the speed of the drill can easily begin to melt the plastic around the hole in your mini or its base causing you to have extra wiggle room that will lessen the support that you gain from pinning.

4. Cut a pin to the correct size

Pinning is one of the reasons that I keep two different pairs of cutters on hand. I use my old beat-up pair to cut through the brass rods or paper clips. Most of the time it will be just fine, but it will dull your blade and over time you will really start to notice.

TIP: once you cut the brass rod it will be sharp. Use a file or some sandpaper to smooth over the part that you keep for future use. This will help minimize the risk of poking yourself with it later. Another thing that you could do is put a small piece of masking tape over the sharp end as a precaution.

I like to use a pair of needle-nose pliers to bend a small loop into the bottom of the pin. This gives it an anchor point underneath the base that also increases the surface area. So I will often put this loop in first before I start to measure the rest of the rod.

I hold the rod up parallel with the model and visually mark the length with my fingertip. After I measure, I mark the spot with a marker and double-check to see if it is long enough. This is the first eyeball measurement. I usually need to cut it shorter after I have it in place. I would rather cut some more off than have it too short though. Over time I have gotten better at eyeballing and my adjustments have been smaller.

I usually cut it so that the mark stays on the piece that I want to use. My theory is that it is much simpler to cut off a little bit more if it is too long than it is to weld on a little bit if it is too short.

5. Dry fit the pin

Before you glue it into place, you should dry fit the pin into the hole that you have drilled into your miniature, it should fit very snuggly. Ideally, your mini should stay attached even without glue for the dry fit.

Next, run the pin through the base from the bottom so that it pokes out the top where your miniature will meet the base. Gently place your model onto the pin and see if there is any gap that is caused by the pin not fitting all the way.

Once you are satisfied with the way that it fits into both the miniature and the base carefully remove your mini from the pin and back the pin out from the base.

6. Glue the pin in place

Because the pin is made out of metal, plastic glue won’t work to hold it in place, even if your base is plastic, instead, you should either use super glue or a two-part epoxy. Personally I almost always use super glue.

Before you add the glue, you can use some fine sandpaper to slightly rough up the surface of the pin to give it extra surface area to hold onto the glue and the mini, this will make it hold your mini in place more securely.

You can either put the superglue onto the pin or put a dot of it on the hole in the base before you feed the pin through for the last time. Personally, I like to put a good drop of superglue onto the hole and let it smear the glue over the rod as it goes through the hole. This has the added benefit of already having some glue in place to add support when the loop you put into the end of the pin is flush with the bottom of your base.

Let the glue dry on the bottom of your pin. I haven’t found a good way to hold it in place with my finger without getting it glued to my skin. After the glue is dry, repeat the process by placing a small dab of glue on the hole in your model and firmly pressing the model into place.

Once your mini is pinned into place it will stay there much better than it would with superglue alone.

These are my recommendations of things that I use all the time when painting miniatures

The Starter Paint Set That I Recommend for small budgets

The Starter Paint Set That I Recommend for large budgets

I like to listen to books on Audible while I paint

Check out these retailers to find hobby products

HOBBY STORES

USA / Canada: Noble Knight Games : eBay (US) :

UK: Element Games : Forbidden Planet

Global: Amazon : Redgrass Games : Warcolours

3D PRINTING

Anycubic : Elegoo : Creality : Sunlu : Flashforge : Matterhackers :